Accelerate product development using advanced CAD tools and 3D printing workflows. I offer end-to-end support—from concept sketches and detailed design to fabrication—enabling rapid iteration and reduced time-to-market.

What I offer (CAD):

I am experienced with designing parts and assemblies for:

- CNC routing and milling of metal and wood

- CNC Laser Cutting

- CNC Waterjet cutting of metal

- 3D printing

- PCB Manufacture and assembly

I can produce work in:

- Autodesk Fusion 360

- VCarve Pro

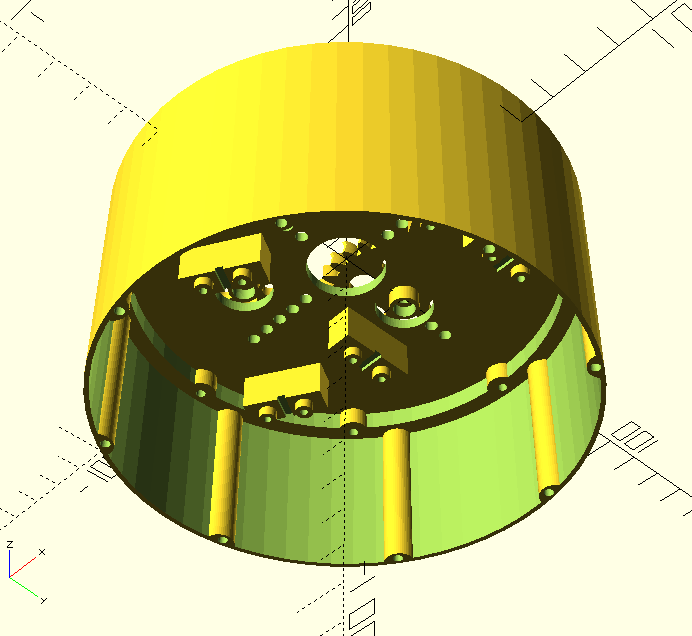

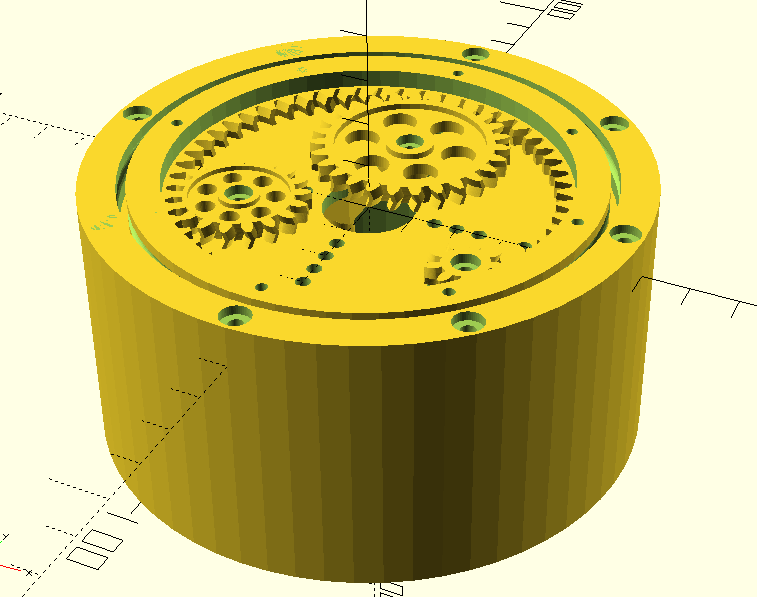

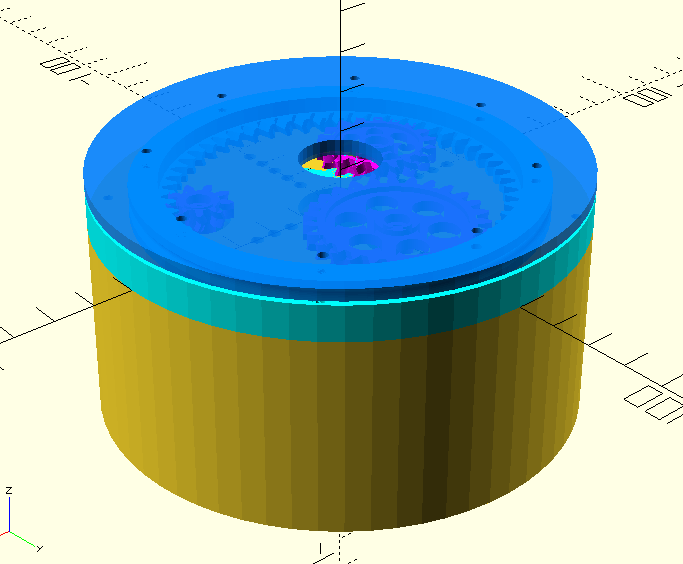

- OpenSCAD

- KiCAD

About OpenSCAD

OpenSCAD is a programmatic approach to CAD modelling that allows for highly parametric builds, in which I have 10 years experience.

What I offer (CAM)

3D printing Service

I have an inhouse capacity for FDM and resin printing. For FDM, I can produce small detailed print via a Bambu Labs X1C Carbon (build volume 256x256x256 mm), or if required I have a large format printer for build volumes up to 420x420x480mm.

General Workshop Fabrication and Services

I can offer basic services in welding, metalwork, acrylics, soldering, assembly and cabinetry.

Instrument Panels

Laser cut acrylic panels, moulded to fit surfaces, durable painted text.

What I Don’t Do

- Design for plastic injection moulding

- Work that requires engineering certificates

- Load bearing or unsafe projects.

- High volume production

- Costume design

- Military applications

Who I Work With

- Agtech firms

- Research institutions and R&D teams

- Industrial and scientific software developers

- Engineering and modelling specialists

- People creating Art/Festival/Museum installations

Why Work With Me?

- Quick turnaround – with drafting and production under the one roof.

- Broad General experience – jack of all trades that can pivot with your needs

- Can do attitude – If the job is within my skill-set lets make some cool stuff. If it’s not in my skill-set, I can generally recommend a specialist. I won’t waste your time and energy by downplaying your vision or ideas.